Cold storage type

By temperature:

High temperature cold storage (±5℃): suitable for fruit and vegetable preservation.

Medium temperature (00℃~--5℃): suitable for cold food after melting.

Low temperature cold storage – 20 ℃): suitable for frozen production, poultry meat food – 10 ℃ aquatic products.

Temporary 23℃: suitable for a short stay before the following cold storage.

By volume:

Small cold storage: <500m³;

Medium-sized cold storage: 500~1000m³;

Large cold storage: >1000m³;

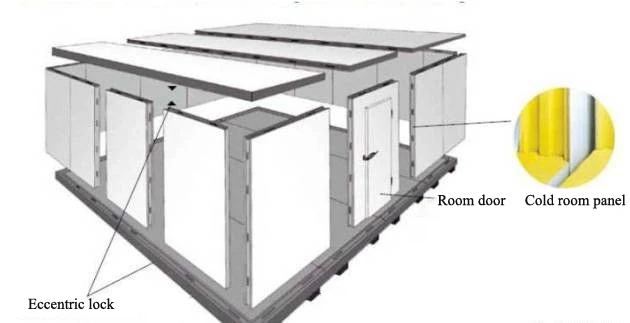

The structure and main equipment of the cold storage

Panel : pre-produced, with fixed length, width and thickness, which can be selected according to the needs of cold room installation. Plates with a thickness of 10 cm are generally used for high and medium temperature cold storage, and plates with a thickness of 12 cm or 15 cm are generally used for low temperature storage and freezing storage.

The structure and main equipment of the cold storage

Under normal circumstances, small refrigerators use fully hermetic compressors. Medium-sized refrigerators generally use semi-hermetic compressors. Large refrigerators use semi-hermetic compressors or screw compressors. When selecting, the ammonia refrigeration compressor can also be considered, because the ammonia refrigeration compressor has high power and can be used for multiple purposes, but the installation and management are more complicated.

Evaporator:

Under normal circumstances, high temperature warehouses use fans as evaporators, which are characterized by fast cooling speed, but it is easy to cause moisture loss of refrigerated products; medium and low temperature cold warehouses mainly use evaporative pipes made of seamless steel pipes, which are characterized by The constant temperature effect is good, and it can store cold in time.

Condenser:

The condenser has air cooling, water cooling and air and water combined cooling methods. Air cooling is limited to small cold storage equipment, while water-cooled condensers can be used in all forms of refrigeration systems.

Expansion valve:

The thermal expansion valve is divided into an internal balance expansion valve and an external balance expansion valve. The inlet pressure of the evaporator is felt under the diaphragm of the internal balance expansion valve; the evaporation is felt under the diaphragm of the external balance expansion valve. outlet pressure.

Accumulator :

store Freon to ensure that the refrigerant is always in a saturated state.

Solenoid valve:

prevent the high-pressure part of the refrigerant liquid from entering the evaporator when the compressor is stopped, avoid the low pressure from being too high when the compressor is started next time, and prevent the compressor from liquid shock. In addition, when the temperature of the cold storage reaches the set value, the thermostat will act, the solenoid valve will lose power, and the compressor will stop when the low pressure pressure reaches the set value. When the electricity is turned on, the compressor starts when the low pressure pressure rises to the compressor start setting value.

High and low pressure protector:

protect the compressor from high pressure and low pressure.

Thermostat:

It is equivalent to the brain of the cold storage that controls the opening and closing of the refrigeration, defrosting, and fans of the cold storage.

Filter drier:

filter impurities and moisture in the system.

Oil pressure protector:

Ensure that the compressor has enough lubricating oil.

Oil separator:

Its function is to separate the lubricating oil in the high-pressure steam discharged from the refrigeration compressor to ensure the safe and efficient operation of the device. According to the principle of oil separation by reducing the airflow speed and changing the airflow direction, the oil particles in the high-pressure steam are separated under the action of gravity. Generally, when the airflow velocity is below 1m/s, the oil particles with a diameter of more than 0.2mm contained in the steam can be separated. There are four types of oil separators commonly used: washing type, centrifugal type, packing type and filter type.

Post time: Nov-14-2022