DJ40 40㎡ cold storage low temperature evaporator

Company Profile

Product Description

|

DJ40 40㎡ cold storage evaporator |

||||||||||||

|

Ref.Capacity (kw) |

7.8 |

|||||||||||

|

Cooling Area (m²) |

40 |

|||||||||||

|

Qty |

2 |

|||||||||||

|

Diameter (mm) |

Φ500 |

|||||||||||

|

Air Volume (m3/h) |

2x6000 |

|||||||||||

|

Pressure (Pa) |

167 |

|||||||||||

|

Power (W) |

2x550 |

|||||||||||

|

Oil (kw) |

4.8 |

|||||||||||

|

Catchment Tray (kw) |

1.2 |

|||||||||||

|

Voltage (V) |

220/380 |

|||||||||||

|

Installation Size (mm) |

1820*650*660 |

|||||||||||

|

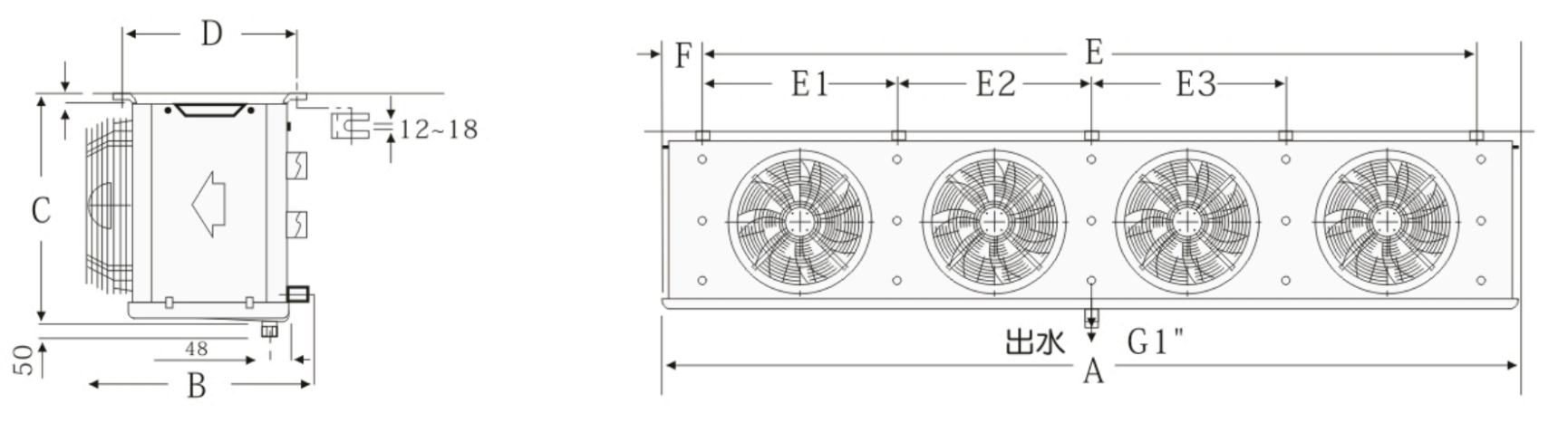

Installation size data |

||||||||||||

|

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

E1(mm) |

E2(mm) |

E3(mm) |

F(mm) |

Inlet tube (φmm) |

Back trachea (φmm) |

Drain pipe |

|

|

1810 |

690 |

680 |

460 |

1530 |

750 |

|

|

95 |

16 |

25 |

||

How to choose a cold storage air evaporator

1.Taking into account the characteristics of the boiling heat transfer in the evaporator tube, the boiling heat transfer heat flux density is calculated, and the heat transfer range of the evaporator is clarified.

2.Considering the influence of the resistance of the refrigerant flow in the evaporator tube on the temperature change of the evaporating environment, clarify the number of flow paths of the refrigerant in the evaporator, the length of the process tube and the basic structural dimensions.Considering the influence of the resistance of the refrigerant flow in the evaporator tube on the temperature change of the evaporating environment, clarify the number of flow paths of the refrigerant in the evaporator, the length of the process tube and the basic structural dimensions.

3.Taking into account the relationship between the main parameters of the bad layer and the main parameters of the cold storage operation, the defrosting time of the evaporator designed according to the boxless working condition is calculated.

The key elements of the cold storage evaporator are as follows:

1. Production volume and main operating parameters.

2. Product features.

3. Public works.

4. Interest on investment expenses and capital acquisition.

5. Staff costs for operation and maintenance, etc.

6. On-site conditions.

7. Mandatory regulations on health and safety, accident avoidance, noise, environmental protection, etc., depend on specific items.