DJ115 115㎡ cold storage low temperature evaporator

Company Profile

Product Description

|

DJ115 115㎡ cold storage evaporator |

||||||||||||

|

Ref.Capacity (kw) |

21.6 |

|||||||||||

|

Cooling Area (m²) |

115 |

|||||||||||

|

Qty |

4 |

|||||||||||

|

Diameter (mm) |

Φ500 |

|||||||||||

|

Air Volume (m3/h) |

4x6000 |

|||||||||||

|

Pressure (Pa) |

167 |

|||||||||||

|

Power (W) |

4x550 |

|||||||||||

|

Oil (kw) |

12 |

|||||||||||

|

Catchment Tray (kw) |

2.2 |

|||||||||||

|

Voltage (V) |

220/380 |

|||||||||||

|

Installation Size (mm) |

3520*650*660 |

|||||||||||

|

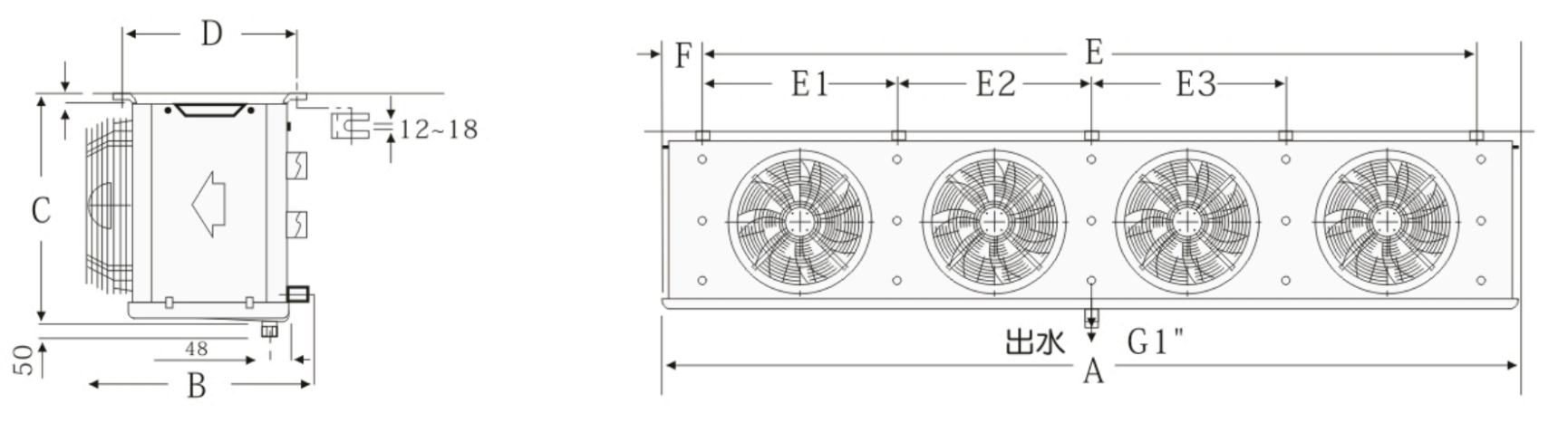

Installation size data |

||||||||||||

|

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

E1(mm) |

E2(mm) |

E3(mm) |

F(mm) |

Inlet tube (φmm) |

Back trachea (φmm) |

Drain pipe |

|

|

3510 |

690 |

680 |

460 |

3230 |

800 |

800 |

800 |

|

19 |

38 |

||

Cleaning method

1. Removal of sundries: Before cleaning, remove all sundries in the system to avoid blocking the sewage pipeline during the process of descaling and descaling.

2. Water flushing and system pressure test: The purpose of water flushing and pressure test is to remove metal oxides and other loose dirt that are easy to fall off in the system. And in the simulated cleaning state, check the leakage of the temporary pipeline to ensure the normal progress of the cleaning process. When the drainage is transparent, the flushing ends.

3. Dosing medicine

Anti-corrosion measures of cold storage air evaporator:

After the evaporative condenser system is cleaned and descaled, and the pre-film is cleaned, it is recommended to add GJ-corrosion and scale-inhibiting water treatment agent for daily operation, otherwise the cleaning and pre-film effect will not last. After cleaning, it can be treated with corrosion and scale inhibition water all year round, which can prevent scaling, extend the service life of the equipment, improve the heat exchange efficiency, and keep the equipment in good condition for a long time, which is safer and more economical than regular cleaning.